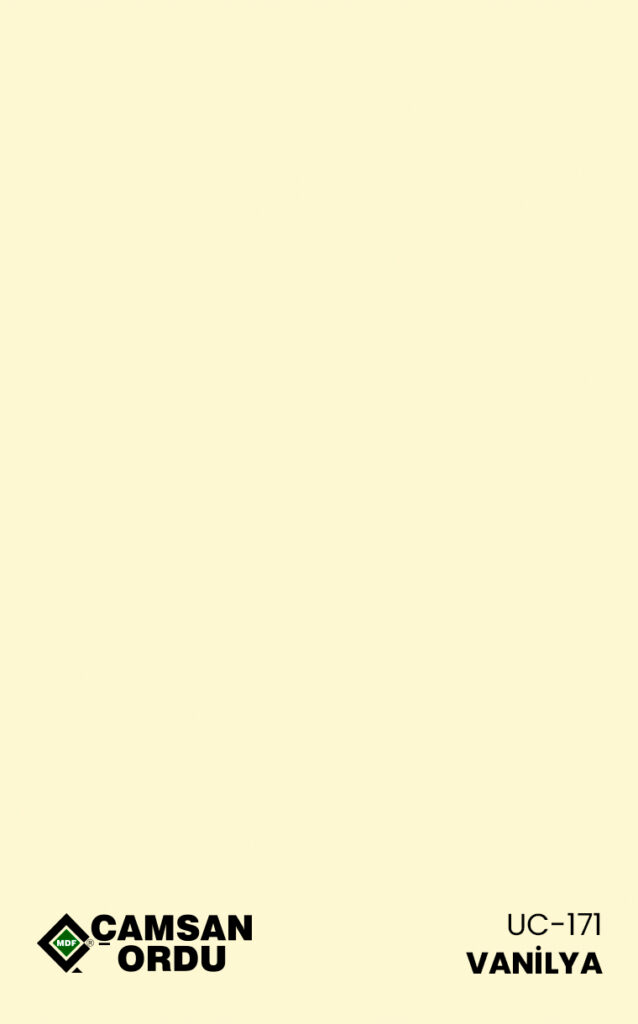

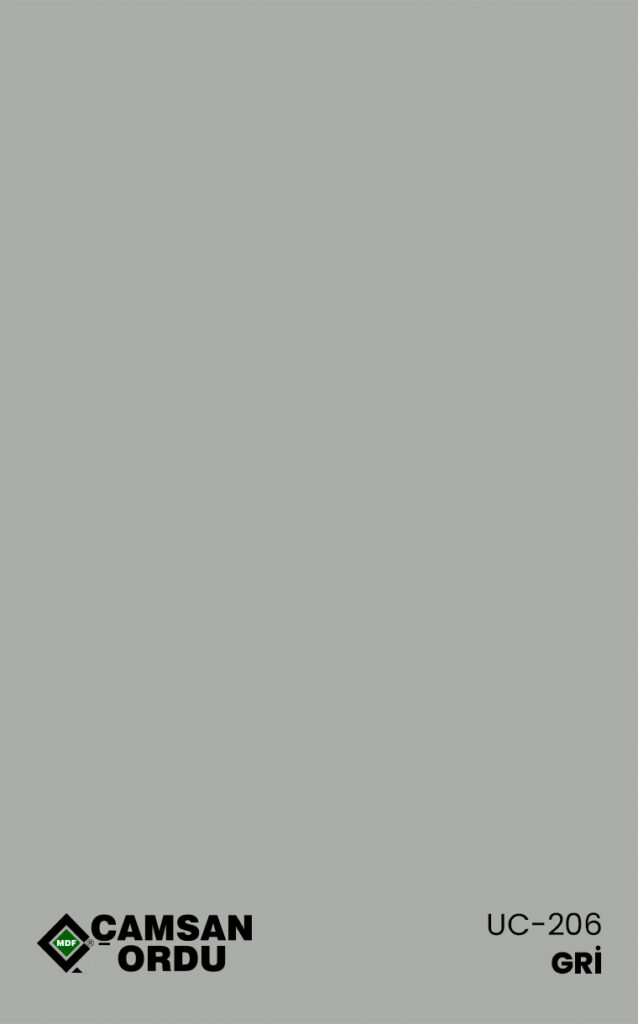

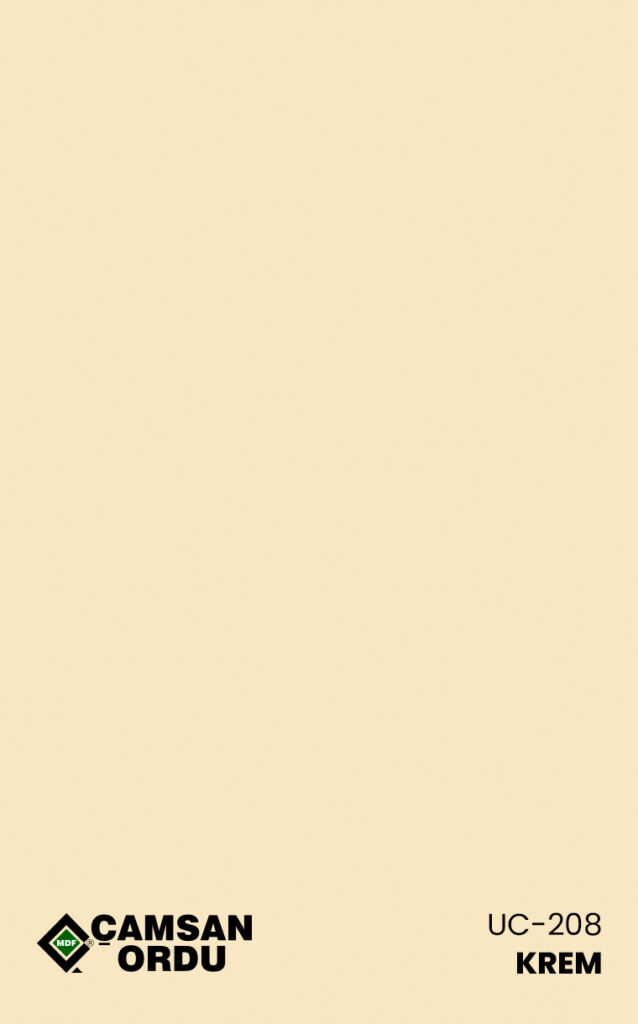

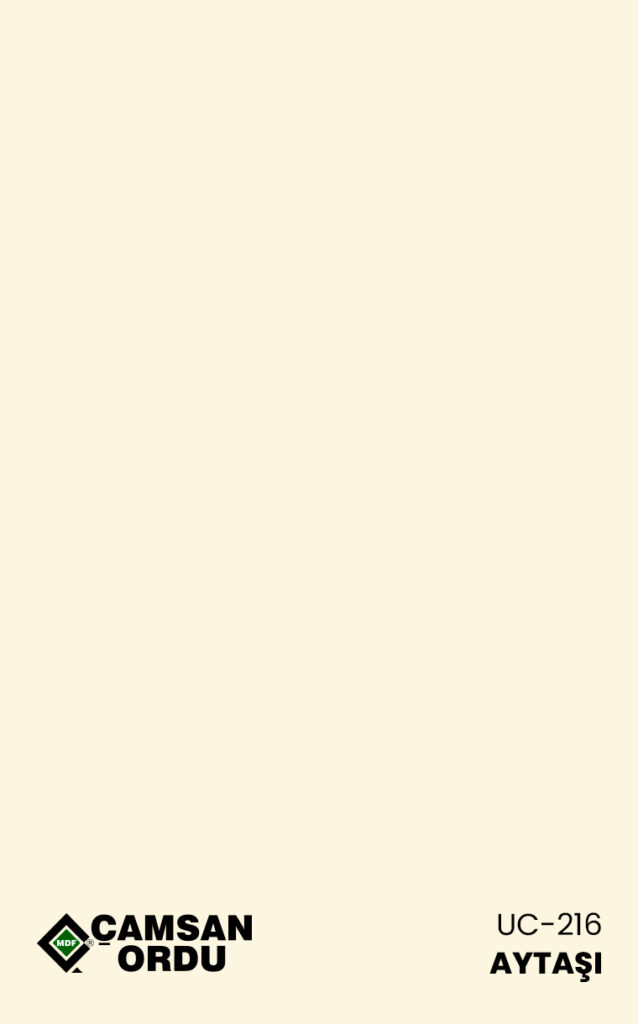

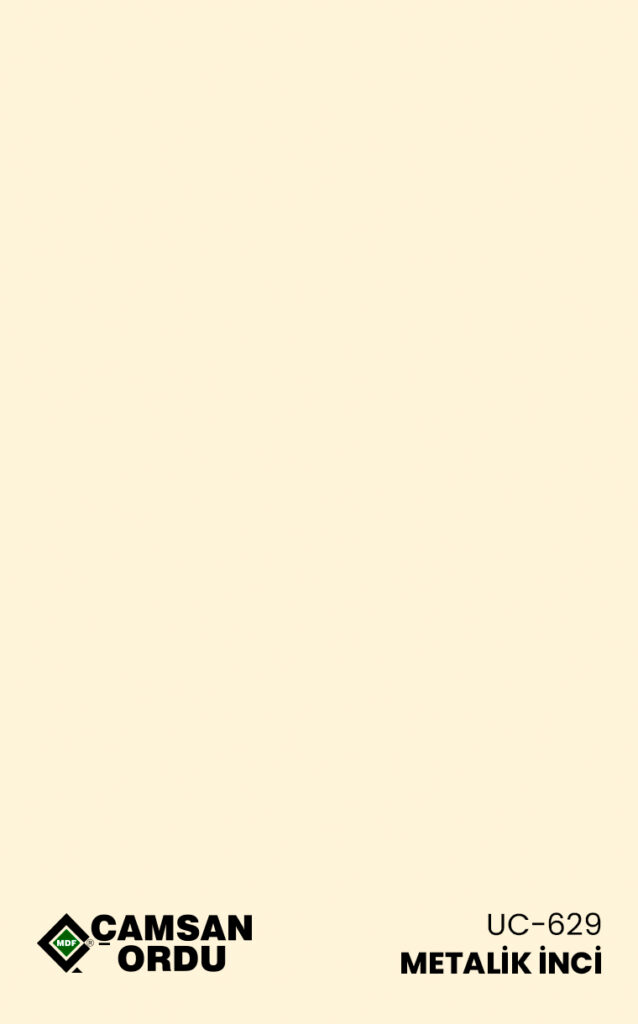

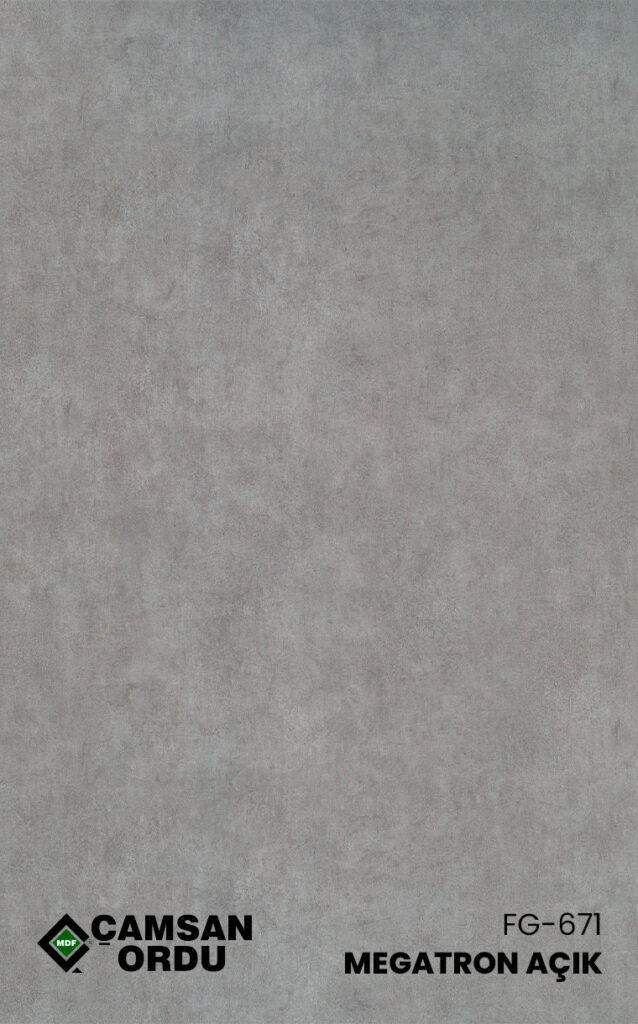

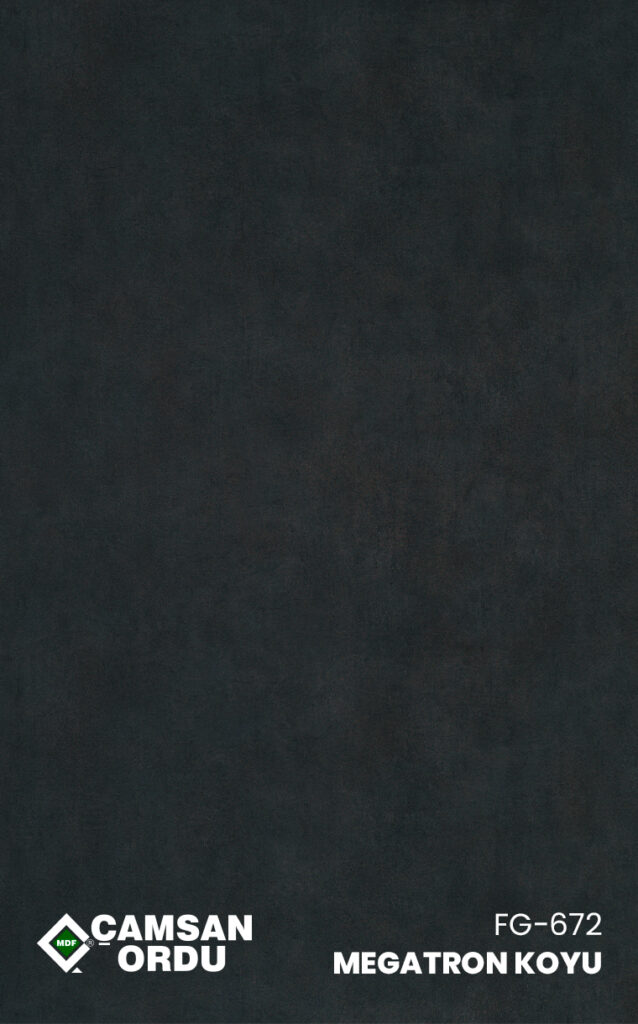

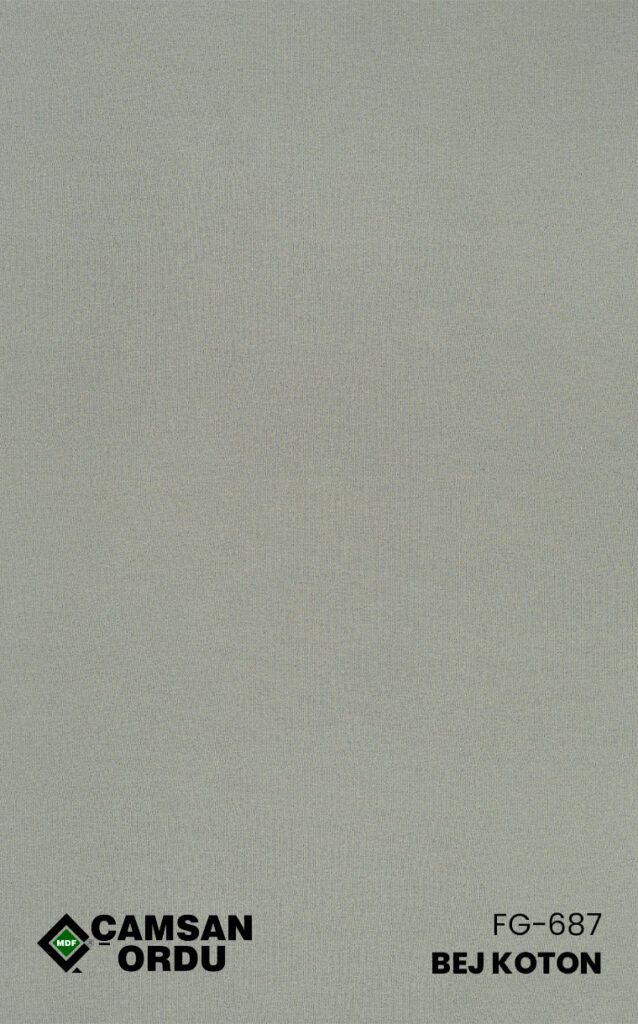

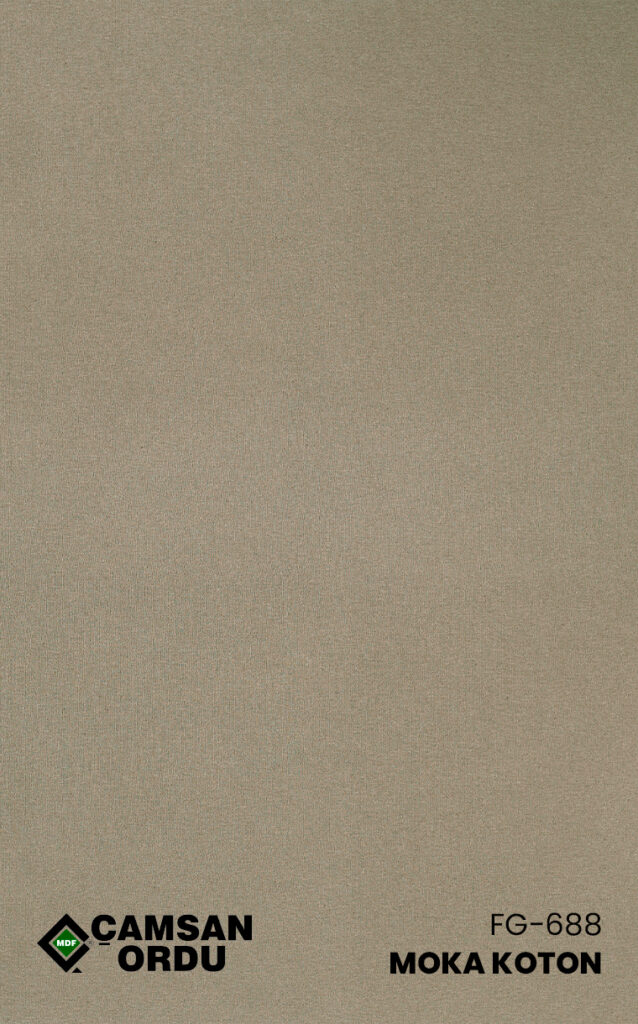

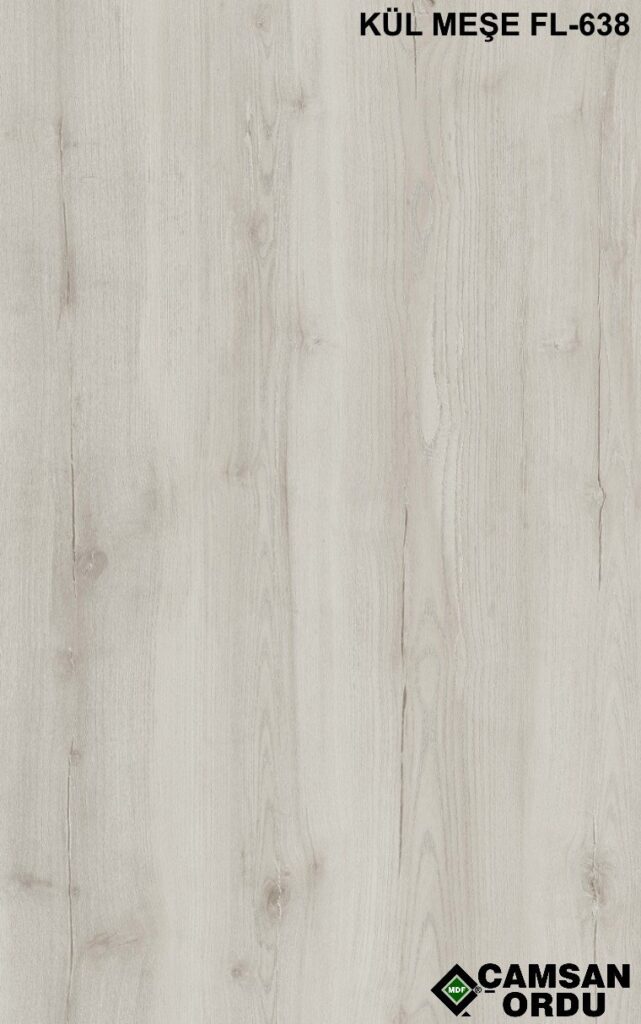

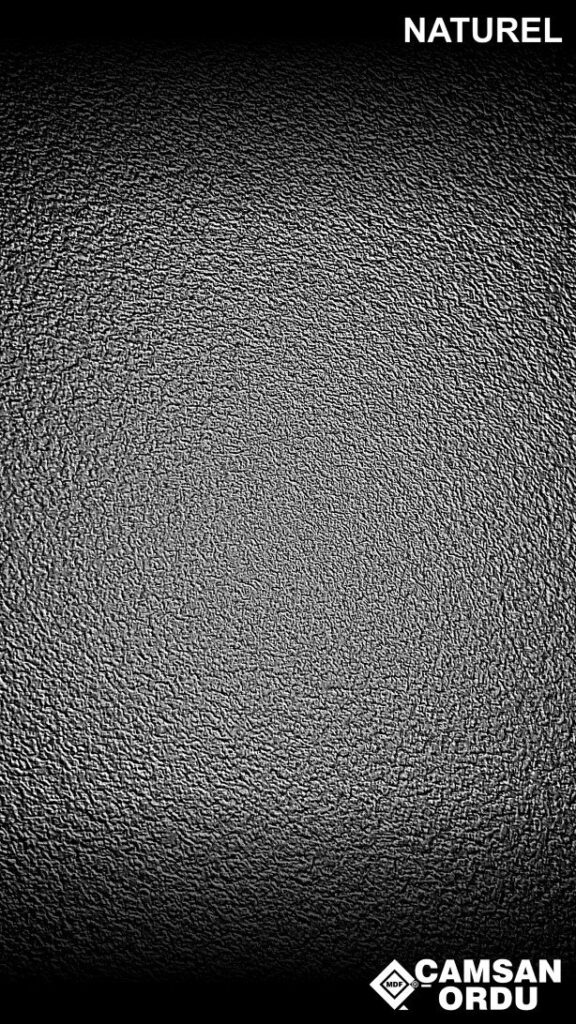

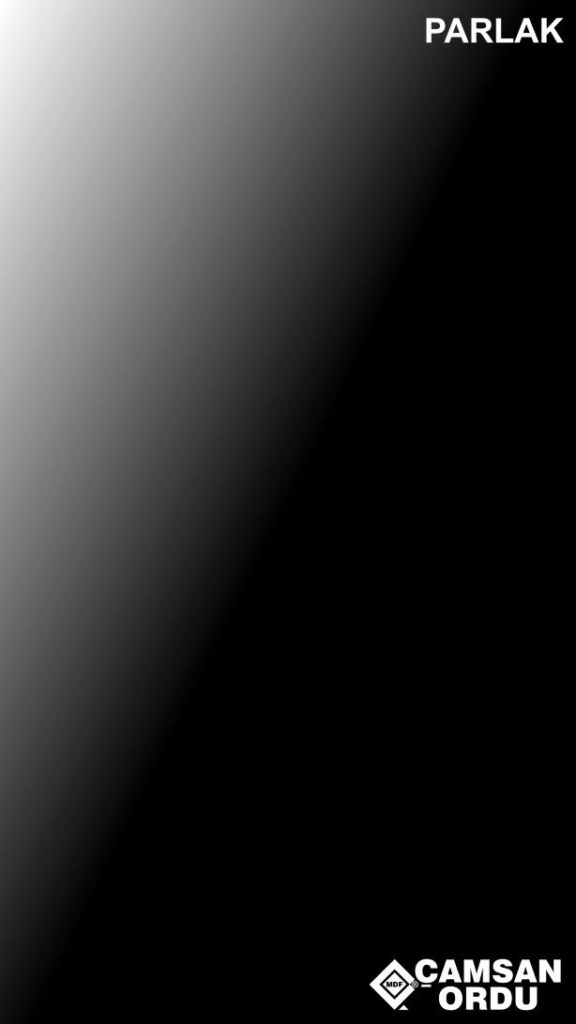

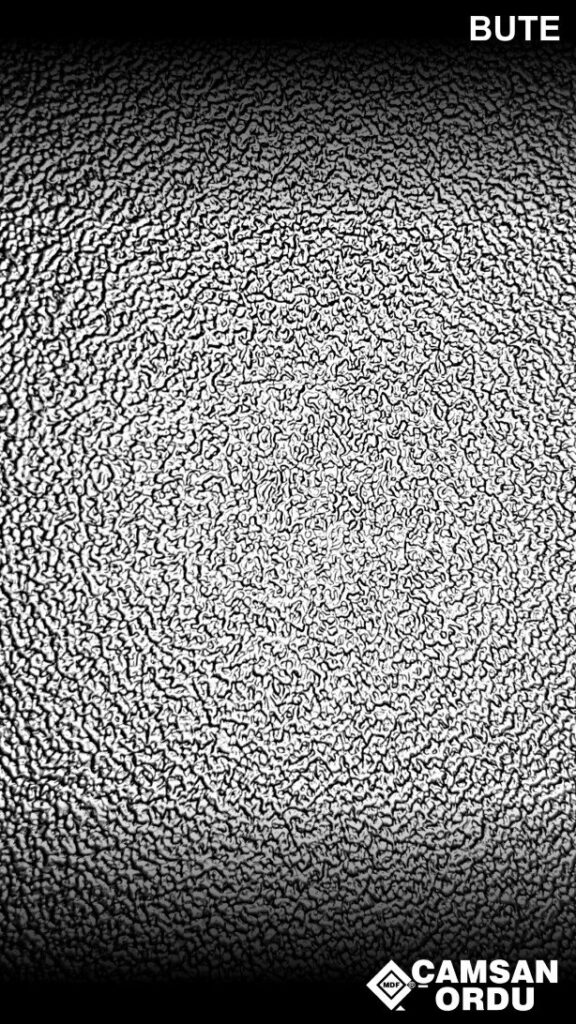

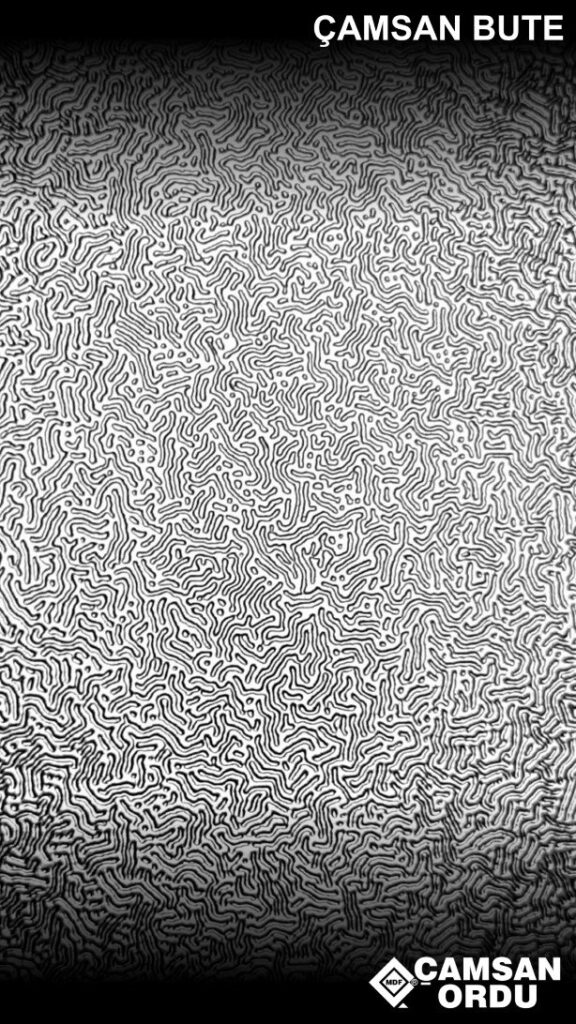

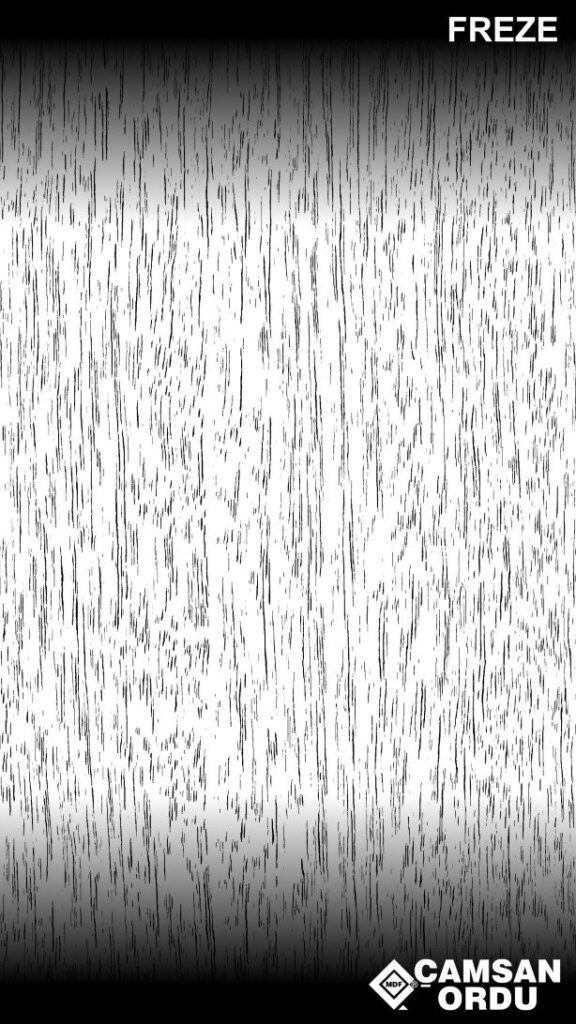

Our Product

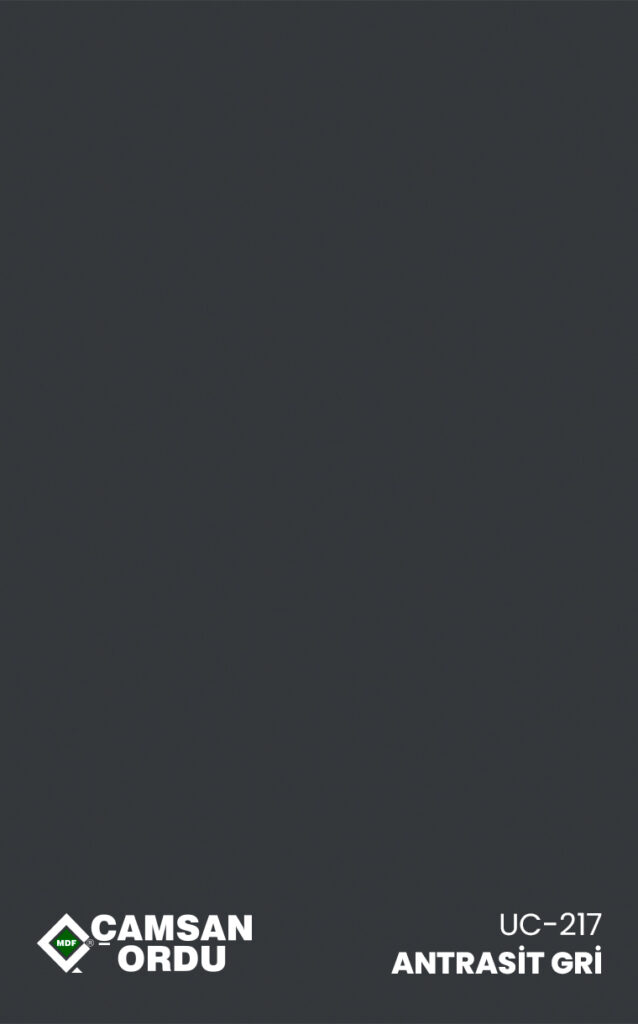

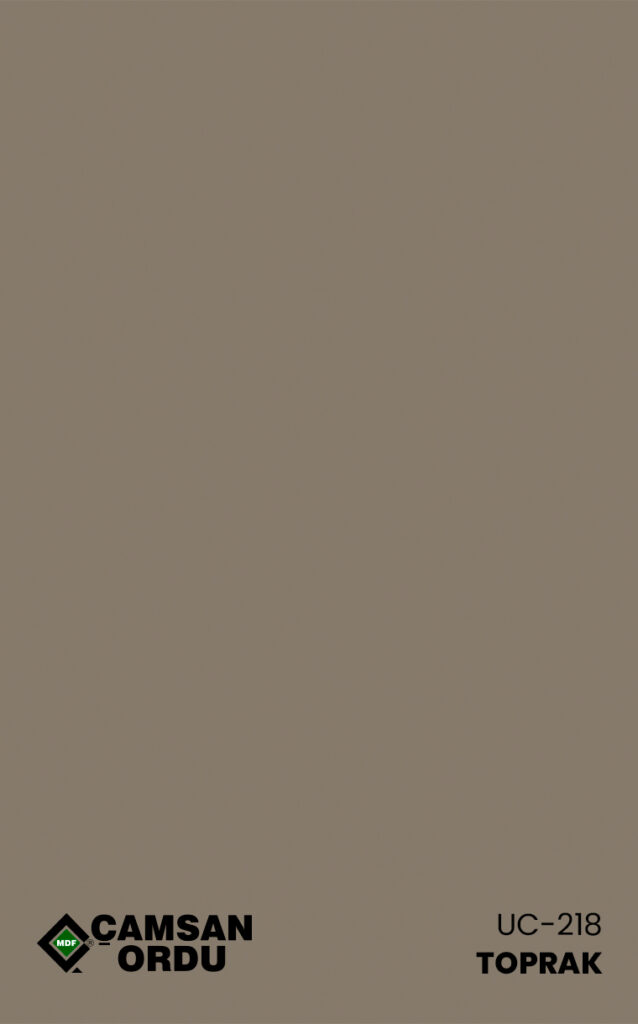

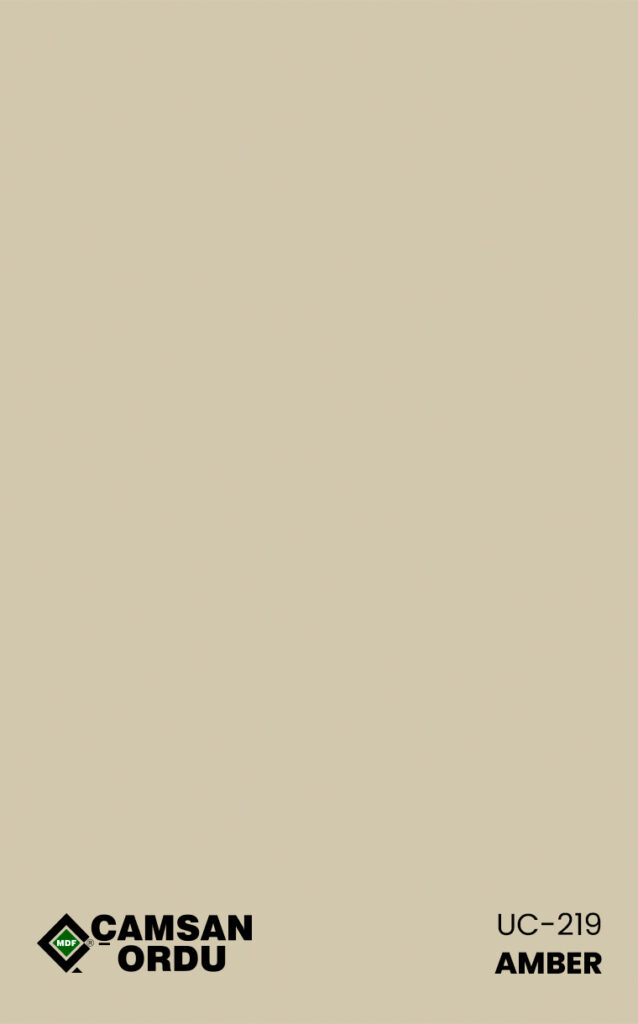

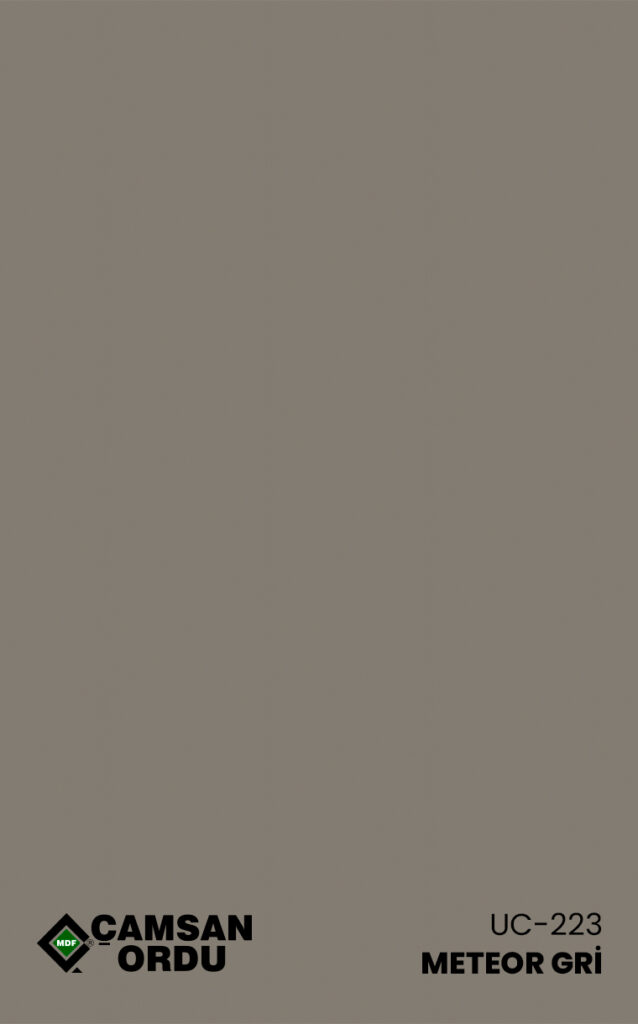

Here you can see our Products and color Catalog

We are first in Türkiye, the Middle East, the Balkans and

Europe’s 4th MDF Manufacturer

Unique and attractive designs, easy handling, stability and perfection all together…

Turkish of MDF

Çamsan Ordu who introduced the MDF to Türkiye; sets new standards with its high experience and advanced technology.

The brand that sets new standards

The highest level of MDF products is here.

What is MDF?

MDF is a product obtained by thermo-mechanically extruding the sheet paste, which is formed after drying fibers obtained from wood or other lignocellulosic raw materials to a certain degree of humidity with the addition of synthetic adhesive, under heat and pressure.

Where to Use MDF?

The equal spreading and density of the fibers at each point of MDF allows both sides of the plate, as well as the edges, to be processed by the machine without any breakage or gaps between the material particles. Thus, MDF can be used successfully in the production of parts such as table surfaces, door panels and drawer faceplates having chamfered edges or profile surfaces.

The surfaces of MDF plates can be covered with all kinds of laminate, resin impregnated paper, foil, and wood plating. The edges of MDF are extremely smooth and tight, and it can be opened by the grooved tongue without gluing solid laths. In addition, it can be shaped in any profile type.

Convenience, Stability and Excellence

Another great advantage of MDF is that it has high bending resistance, elasticity mode, screw and nail withdrawal resistance. The main features of “Çamsan Ordu MDF” are that they are easy to process in a machine, the perfection of stability, the almost immutable dimensions, and the advantage of being provided in standard dimensions. Additionally, its both surfaces are sanded and leveled, there are no defectives such as knots, cracks or splinters in any part, each point is at the same density, it is ready to use, and does not require any preparation, it is suitable for all kinds of lacquers, paints, varnishes and can be covered with materials such as wood veneer, PVC, laminate and melaminated decorative paper, and can perfectly hold the screws that will enter both sides and the edges.

Just as any application, our profiling products are uncompetitive for cover manufacturing applications.

Error Free Product

There are no construction or cutting errors in protrusions, holes, edges and corners.

Standard Production

The production sizes in the factories in Ordu are standard. The plate sizes are 1830×3660, 2100×2800, 2100×3660 mm and their thicknesses are between 8 mm and 30 mm.

Unrivaled

It is also an unrivaled product for cover applications.

What is MDFLAM?

Decorative papers used for Melamine coated MDF (MDFLAM), which is a product obtained by pressing the decorative papers impregnated with melamine resin onto MDF boards under certain temperature and pressure, are imported from Europe’s leading paper producers and melaminated in Çamsan Ordu’s impregnation facilities. The production sizes in the factories in Ordu are standard. The plate sizes are 1830×3660, 2100×2800, 2100×3660 mm and their thicknesses are between 8 mm and 30 mm.

The plated products of “Çamsan Ordu” manufactured as MDFLAM and SUNTALAM, have no protrusions and pits, no construction and cutting errors on the edges and corners.

Just as any application, our profiling products are uncompetitive for cover manufacturing applications.

Superior surface quality

Save both material, time and labor with its high paint holding ability and superior surface quality.

High savings

It saves 13% -21% ** lining material, drying time saving, time saving up to 40% and sanding labor savings.

Advantageous

It can be used safely in all paint types.

What is Astarlam?

Our new product “Çamsan Ordu PRIMARLAM”, which saves material, time and labor in lacquer applications, and also it offers high paint retention ability and superior surface quality. “Çamsan Ordu PRIMARLAM” can be used safely with all types of paints.

ADVANTAGES OF “ASTARLAM”;

In the Finished Product,

Compared to raw MDF, 13%** saving of undercoat material when using UNDERCOAT/UNDERCOAT,

Compared to raw MDF, 21%** saving of undercoat material when using UNDERCOAT/WHITE LAM or UNDERCOAT/WHITE SHINY LAM,

It saves up drying time, as it can cover the surface with a thinner and single layer.

It saves up time up to 40% on delivery process depending on the application methods.

Thus, you will not need repeated sanding processes.

In the serial production of Lacquer Furniture and Door, you will get immediate economical results.

Samples can be sent upon request.

**Applications that were made with handguns were taken into consideration. Automation applications may differ.

Kastamonu, Turkey’s Tree Region

It consists of Turkey’s largest perforated particle board (Tubular Chipboard) production facility with its modern integrated facilities in the district of Ihsangazi in our province, on an open area of 285,000 m² and a closed area of 22,000 m².

It is the only chipboard factory in Turkey and the Middle East that produces perforated chipboard with German technology. Turkey is a leader in the sector with our modern facilities for perforated chipboard = tubular chipboard, which is greatly needed by sellers and manufacturers, with the possibilities to meet the needs of the Middle East and Balkan countries.